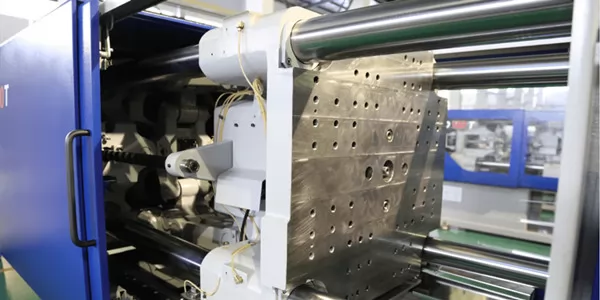

The injection molding machine has undergone many years of development. There are two types of presses and machines used in the injection molding process: hydraulic and electric, and hybrid injection molding machines.

Until a Japanese company introduced the first electric motor in 1983, hydraulic injection molding machines were the only available option. Since then, motors have become more and more popular. However, hydraulic presses are still the most widely used type everywhere. An important reason why hydraulic presses continue to dominate injection molding is that the machines themselves are cheaper than electronic machines. But why do many people still recommend the use of all-electric injection molding machines? Next, I will give you eight reasons to buy an all-electric injection molding machine.

1. Clean

-

No hydraulic oil

Standard hydraulic and hybrid injection molding machines require hydraulic oil to drive the clamping movement of the injection molding machine and the injection unit. All-electric injection molding machines use servo motors to drive all machine movements and do not require hydraulic oil. All electric injection molding machines will not leak oil because they do not use oil. Therefore, there will be no dirty and slippery oil leakage in the production workshop. After the hydraulic oil has a life cycle of more than 2 to 5 years, you will no longer need to change the hydraulic oil. There is a big difference between having to use hydraulic oil and not having to use hydraulic oil. In industries requiring food packaging, medical molding or clean rooms, a clean environment is required. Oil leakage will become a serious problem, but the all-electric injection molding machine does not have this problem.

2. Relatively little maintenance

-

No need to change hydraulic oil

The life cycle of hydraulic oil in a machine depends to a large extent on the time of use and the quality of the machine itself. According to the usage and environment, the service cycle of hydraulic oil is different, but it is inevitable that both hydraulic and hybrid injection molding machines need to replace the hydraulic oil. Hydraulic oil is also a significant cost. The all-electric injection molding machine can provide a clean and quiet working environment, making it an ideal machine for food packaging and medical molders.

-

Less equipment

For customers who only use all-electric injection molding machines, it is common for their factories to have only chillers. This is because their machines no longer need a high-temperature cooling circuit, but only a low-temperature cooling circuit for the mold and the feed port. Owning less equipment means less capital investment, less maintenance and maintenance costs, less energy consumption and lower expenses.

3. Power saving

-

Energy-saving working status

Contrary to the name of the all-electric injection molding machine, compared with the same hydraulic injection molding machine, the all-electric injection molding machine is very energy-saving. Comparing the standard hydraulic injection molding machine and the all-electric injection molding machine by running the same parts and molds, the all-electric injection molding machine can save energy by 50% to 70%.

This is because in a standard hydraulic injection molding machine, the hydraulic pump is always on when the machine is running. It must keep running to circulate the oil, and it will generate heat as long as the machine is running. On the other hand, since the all-electric injection molding machine consumes power only when the servo motor rotates to drive movement, most of the production cycle is spent idling, especially in the cooling phase of the cycle.

A standard hydraulic injection molding machine has one or more pumps that generate hydraulic pressure, and a valve that directs pressure to the hydraulic mechanism to build up the pressure according to the required movement. All-electric injection molding machines do not have a central motor, but use separate motors designed for each function required by the entire machine. This means that the motors can be left unused until their specific functions are needed.

-

No hydraulic cooling required

Energy saving does not stop at injection molding machines. With the elimination of the hydraulic pump circuit, the hydraulic system also needs to be cooled. Since all electric injection molding machines have no hydraulic system, machine cooling is not required. The only cooling you may need is the mold and feed port. This will bring additional savings because you do not need additional water pipes and permits to place them.

4. High precision

All electric injection molding machines have the highest precision. This is because these machines use electric servo motors to drive their movement. This type of motion allows the process to completely eliminate the fluctuations and inaccuracies of hydraulically driven motion and its inevitable pressure curve.

5. High repeatability

All the fine adjustments that can be made by the entire motor. All-electric injection molding machines are considered to have "closed loop" control, because they control every movement through the physical gear rotation of the servo motor, and can continuously monitor and control their position and speed, so that they have very strict tolerances, regardless of Environmental conditions. All-electric injection molding machines are very suitable for manufacturing the most complex, difficult and thin-walled parts.

6. High synchronization

The all-electric injection molding machine has multiple electric servo motors. These motors are connected to pulleys and belts. These pulleys and belts work on a ball screw mechanism. These mechanisms drive functional movement, that is, the pressure plate opens and closes. The ability of all motors to perform compound movements (driving multiple functions at the same time) is one of the reasons why motors often shorten cycle times compared to standard and hybrid injection molding machines. You can "instant eject" or eject your parts before fully opening the mold, and you can start to restore the screw while opening and closing the mold. Hydraulic injection molding machines can only handle one movement at a time because they usually have only one hydraulic circuit to drive the movement.

7. High reliability

All-electric injection molding machines are the most reliable among different types of injection molding machines. This is because unlike standard hydraulic injection molding machines and hybrid injection molding machines designed decades ago, they are usually more suitable for lower price ranges, and all-electric injection molding machines usually use the most advanced technology. The all-electric injection molding machine is also very quiet when running, most of which run at 70db or below. This means that your employees do not need to wear hearing protection when operating the machine.

8. Automation

Many all-electric injection molding machines have safety functional standards, such as mold safety to prevent extruded parts and foreign objects in the mold, prevent cold screw rotation, and prevent accidental rotation of the injection screw when the plastic is still solidified when the machine is idle. Most machines will have a centralized lubrication system or an automatic lubrication system, which automatically pumps the grease to the tie rods, toggle links, linear guides and other locations that need lubrication on the mold. When the grease level is low, some machines have sensors to alert the grease reservoir or the fuel tank of the low level to remind your maintenance team to refill the grease or replace the fuel tank.

Conclusion

Since there is no risk of oil contamination, electric injection molding is very suitable for clean room applications. Due to its high precision, the all-electric injection molding machine is ideal for small and medium-sized parts and medical products (such as petri dishes and syringes).

Using an all-electric injection molding machine, you will continue to run production without oil, less maintenance, higher accuracy, higher repeatability, energy saving, a quieter working environment, and a machine that is easier to maintain.

The rise of the all-electric injection molding machine provides more choices for the power source of the injection molding machine. The rapid response, precision, and intelligence trend makes the all-electric injection molding machine more advantageous in the future development. The only drawback is that its clamping force is not enough. Strong, full hydraulic injection molding machines are still needed in the production of some large injection molded parts. For now, full electric and hybrid injection molding machines will be an important direction for the development of injection molding machines in the future.

If you need to buy an all-electric injection molding machine, you can choose Anstrength's all-electric injection molding machine. Anstrength is an all-electric injection molding brand under NINGBO CHUANGJI MACHINERY CO.,LTD. Focus on the manufacture of high-precision products such as optics, precision electronics, medical treatment, and precision connectors. Its excellent precision and high injection speed make it a leader in the high-end machinery industry. It is currently the leading brand of direct-drive all-electric injection molding machines .

Contact us now to get the latest quotation and the most detailed information.