Generally speaking, customers who have been engaged in the injection molding industry for many years have the ability to judge and choose the appropriate injection molding machine for production. However, under certain circumstances, customers may need the assistance of the manufacturer to decide which injection molding machine to use, or even the customer may only have product samples or ideas, and then ask the manufacturer whether the machine can be produced, or which model is compared to be suitable for. In addition, some special products may need to be equipped with special devices such as pressure accumulators, closed circuits, injection compression, etc., in order to produce more efficiently. This shows that how to determine the appropriate injection molding machine to produce is an extremely important issue. The following information is provided for readers' reference .

How to choose injection molding machine

Whether the type and specification of the injection molding machine are correct before use will have a greater impact on the production cost, quality and production efficiency of the injection molded products.

-

Model number

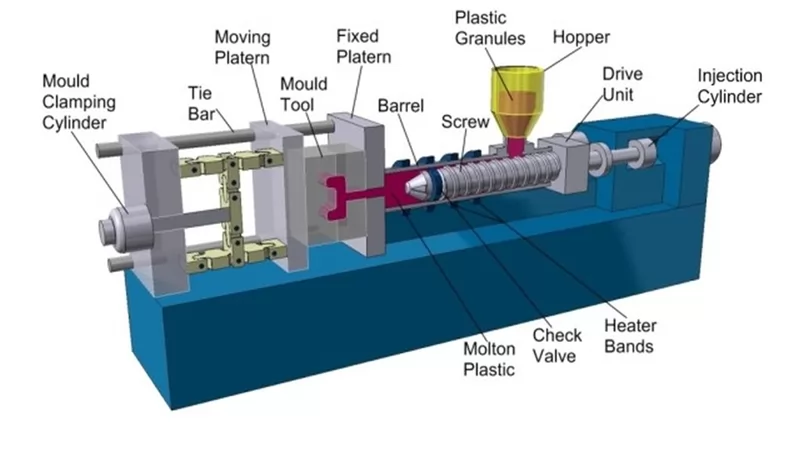

Before selecting the specifications of the injection molding machine, first check the performance parameter values of the injection molding machine in the product manual provided by the injection molding machine manufacturer. These parameter values represent the main performance characteristics of the injection molding machine . According to some technical requirements of the plastic products to be produced, such as the types of raw materials for the products, the brand, the weight and the external dimensions of the products. To find the parameter values close to it in the manual, the injection molding machine model corresponding to these parameter values is the injection molding machine to be purchased.

-

Specifications

At the same time, we must also understand whether the working accuracy, speed and product accuracy level of the injection molding machine meet the molding conditions of the product.

The key comparison data in the specifications and models include: the proportional relationship between the quality (or volume) and the external dimensions of the injection molded product and the parameter value in the equipment,

that is, the proportional relationship between the manufactured weight and the theoretical injection volume (or volume) of the injection molding machine: product The size requirements of the length (or height) and the sum of the thickness of the forming mold (or the thickness of the mold on the moving template) and the travel distance of the moving template of the injection molding machine.

-

Size

In addition, it should also be verified that the size of the mold structure to be installed on the injection molding machine conforms to the conditions of the injection molding machine:

- The distance between the tie bars should be larger than the width and height of the mold to facilitate the assembly of the mold.

- The size of the template conforms to the size requirements when the molding die is installed and fixed.

- The width and height of the mold must conform to the minimum mold size recommended by the injection molding machine.

Well-known injection molding machine manufacturers

-

ARBURG

Having created its first injection molding machine in the fifties, Arburg is one of the most established injection molding machine manufacturers in the market. It's also one of the largest, with 33 locations across the world, with its largest production site still at its family factory in Lossburg.

-

Haitian International

One of the major Asian manufacturers, Haitian International offers both electrical and hydraulic machinery and a service that employs 6,390 people internationally. By putting its focus on innovations, details and customer service, Haitian says it enables the people that buy its machinery to be as flexible in their manufacturing processes as possible.

-

NINGBO CHUANGJI

ocated in Yuyao, China's plastic products kingdom. It is a high-tech enterprise specializing in plastic injection molding machinery. Engaged in the design, development, manufacturing, and optimization of injection molding machines for many years. Since the official launch of LOG in 2007 , the company's sales network has spread all over the world. More than 45 distributors have been established in mainland China. In Brazil, Turkey, Russia, Iran, Mexico and other more than 20 overseas countries have dealers and service outlets. Country, serving local distributors for many years, and familiar with the local market. Has three major sub-brands: LOG, Maritime, Anstrength. Produced separately: standard hydraulic machine, high-precision hydraulic machine and all-electric injection molding machine.

-

ENGEL

Similarly, the Engel group has nine locations across the globe, meaning that it can provide a worldwide service too. Offering both hydraulic and electric models, Engel promises a clamping force from its machines of between 280 kN and 55,000 kN.

Why choose a Chinese injection molding machine supplier?

-

Low cost

The American Forbes biweekly website published on April 2 an article titled "Practice Makes Perfect: Why Chinese Manufacturers Have A Production Advantage" by Professor Willy Shih of the Harvard Business School in the United States, saying that he has a huge domestic market to practice. And optimize production, which is a huge advantage for manufacturers. And now Chinese manufacturers have this advantage. The article said that manufacturers of almost every product rely on learning-they are increasingly good at producing their own products and reducing production costs.

-

Professional

Yuyao, China is the largest manufacturer of plastic products and injection molding machines in the world. It also has many years of professional manufacturing and export experience and services, and is familiar with local humanities, laws and import and export rules, as well as local market changes. Buyers from many parts of the world come to Yuyao, China.

-

Huge market

China has supplied injection molding machines in about 200 countries around the world. The compound growth rate of China's injection molding machine market will be 6% from 2017 to 2020. In 2020, the market scale of China's injection molding machine will be 53.6 billion yuan. The Chinese injection molding machine market is expected to account for one-third of the global market by 2019. According to this calculation, the compound growth rate of China's injection molding machine market will be 6% from 2017 to 2020, and will reach a market size of 53.6 billion yuan by 2020. These figures are also steadily increasing year by year. In addition, today's Chinese consumer market has a multi-level and strong consumption situation, which also forces Chinese companies to become bigger and stronger in their respective fields, to optimize and update more subdivided products, and to The high-end field is continuously studied, and the price is kind and stable.

-

Complete supply chain

Chinese suppliers can have a complete and tough supply chain from design to manufacturing, such as electronic products, 5G technology, high-speed rail, injection molding machine related products. We have advanced technology, low technology cost, complete business model, mature team, professional equipment, can be readily available, and can be purchased at one time. So it can be done in China, as long as the buyer puts forward demand, Chinese manufacturers can help the buyer complete the supply of goods through the train.

How to purchase injection molding machines from China

Ningbo Chuangji has sold and served for many years in the United States, Mexico, Russia, South Korea, Turkey, Indonesia, Vietnam, Thailand, Brazil, Colombia, South Africa and other countries, has many years of professional manufacturing and export experience, and is familiar with local humanities, laws and import and export rules, And local market changes. And with high-quality product introduction, product installation and care plan, as well as after-sales service and security. Provide twenty-four seven online service worldwide , including injection molding machine parts manufactured in all generations can get professional services. If you're looking for injection molding machines or its manufacturer recently, it's a good choice.

You can contact us immediately to get more information.