This comprehensive guide will help you understand the essentials of injection molding, the interplay between injection molding machine and molding costs, and the economic fundamentals of the process. You'll also gain insights into the pricing of different types of injection molding machines and the factors that influence the cost of the molding process. With the right strategies, you can optimize these costs to maximize your business's profitability. As we look to the future, we'll also discuss the potential impact of automation, AI, and sustainable practices on injection molding costs.

1.Understanding Injection Molding: The Basics

Injection molding is a cornerstone of modern manufacturing. This process involves the use of an injection molding machine, which has a role in the creation of a myriad of everyday products, from bottle caps to automotive parts. However, understanding the intricacies of the injection molding process and the associated injection molding machine cost can often seem complex, especially for those new to the industry.

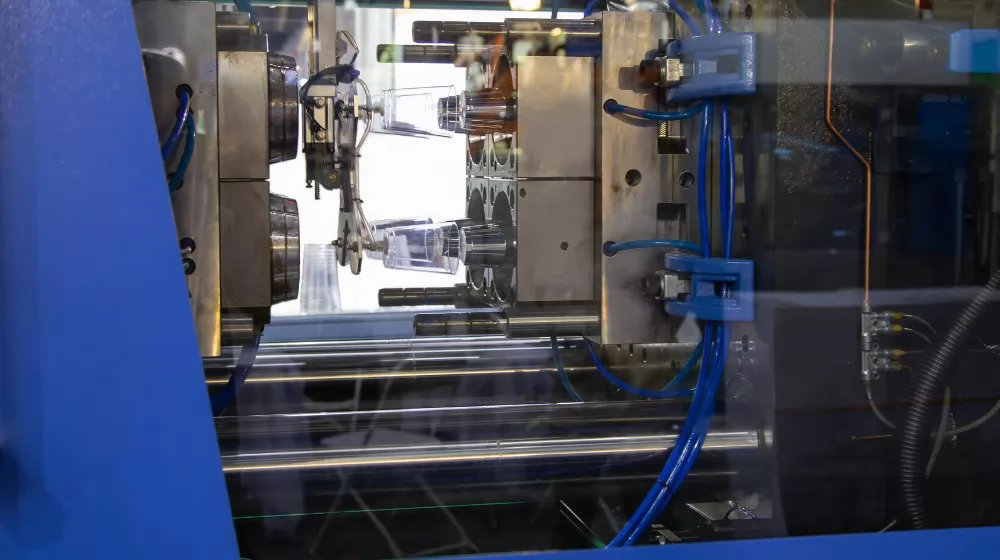

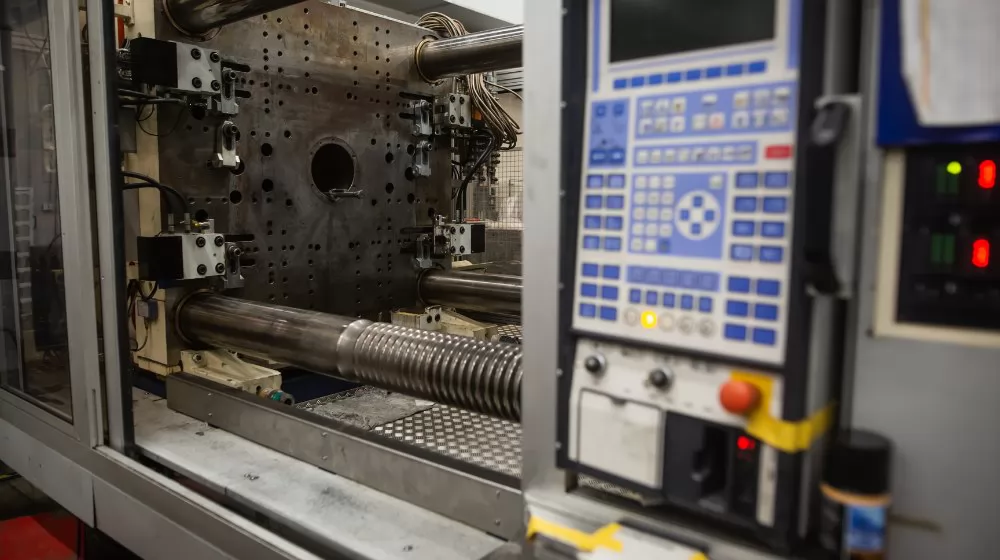

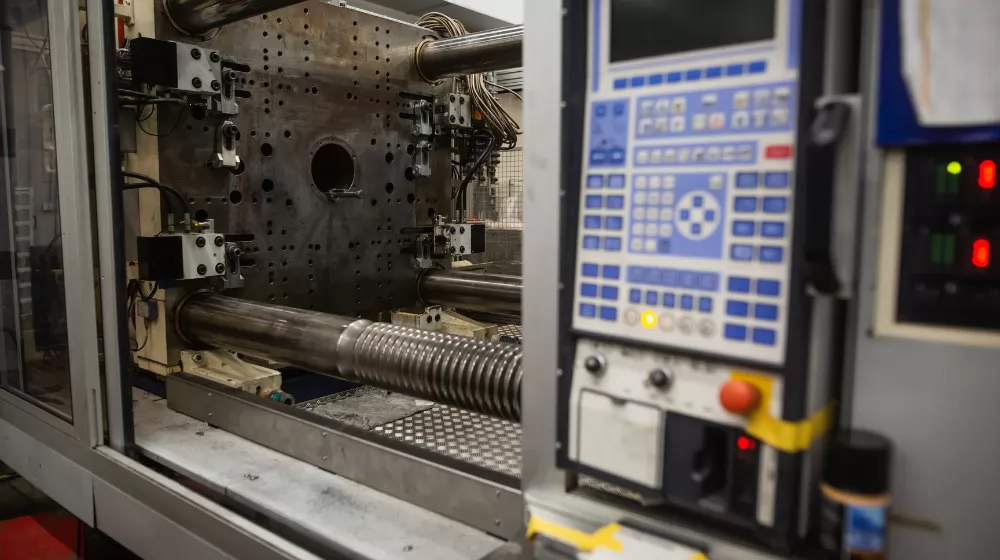

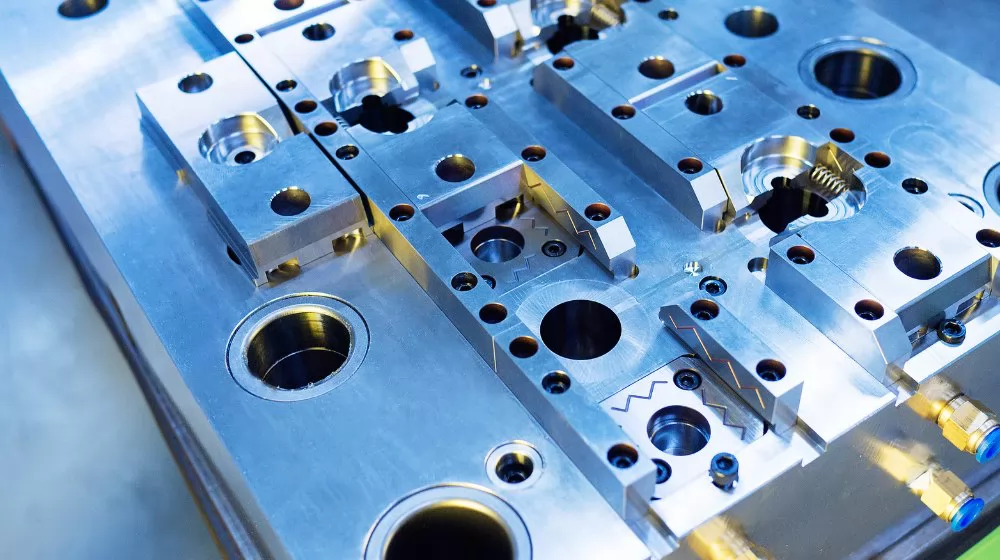

At its core, injection molding is a process where molten plastic material is injected into a mold under high pressure. The material is then cooled and hardened within the mold to take the shape of the cavity. The key player in this process is the injection molding machine, a piece of equipment that heats the plastic pellets to a molten state and then injects them into the mold.

While the process may seem straightforward, it is the machine's intricacies and the mold's design that can significantly influence the injection molding cost. Consequently, the careful analysis and understanding of these factors are crucial for any business looking to invest in injection molding for their manufacturing needs.

2.The Interplay Between Injection Molding Machines and Molding Costs

When discussing the injection molding cost, it's important to understand that the injection molding machine cost is only a part of the overall equation. The cost of molding is a cumulative sum of various factors that include the machine's price, its operation, the mold design, and the materials used.

Typically, the initial investment in an injection molding machine can be substantial. Factors such as the machine's capacity, its automation level, and its energy efficiency can significantly influence the price. However, an efficient machine can provide long-term cost savings by reducing energy usage, minimizing waste, and optimizing production time.

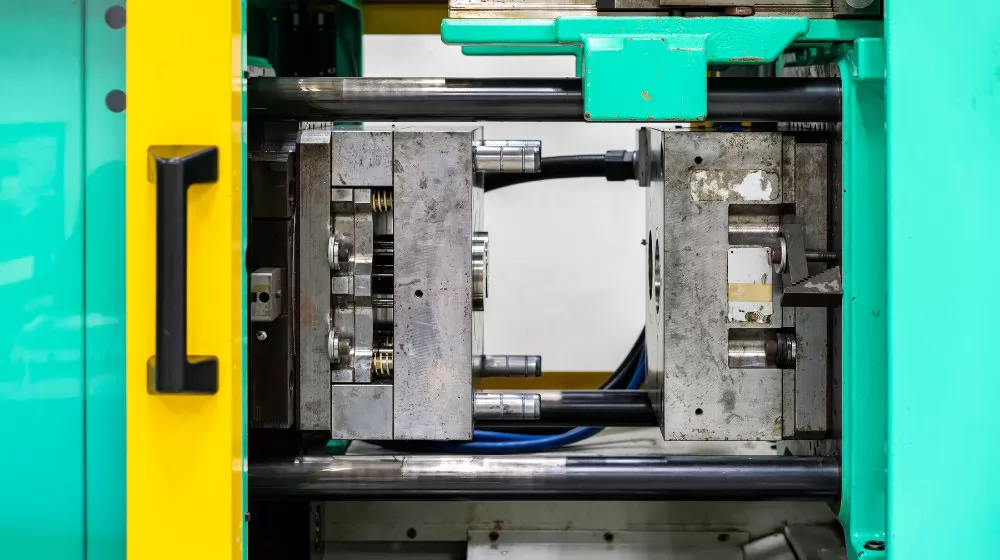

Similarly, the mold's design and the materials used can influence the injection molding cost. A complex mold design may require a higher initial investment but can result in better-quality products and less waste. On the other hand, choosing cheaper materials might reduce the initial mold cost but could lead to higher maintenance costs and lower-quality end products.

Therefore, understanding the interplay between the injection molding machine cost and the mold cost is crucial for making informed decisions and optimizing the overall expenses.

3.The Economic Fundamentals of Injection Molding

A. The Business of Injection Molding

The business of injection molding is one where precision, speed, and efficiency are paramount. With the ever-increasing demand for complex and high-quality plastic parts, businesses need to understand the economic fundamentals of injection molding to stay competitive. This includes not only understanding the injection molding machine cost but also the cost of raw materials, labor, and maintenance, among others.

B. Factors Influencing the Cost of Injection Molding Machines

Several factors influence the injection molding machine cost. First, the type and size of the machine: larger and more complex machines tend to cost more. Second, the machine's automation level: machines with advanced controls and automation features can be pricier, but they often offer better precision and efficiency. Third, the machine's energy efficiency: while energy-efficient machines might have a higher initial cost, they can lead to substantial savings in the long run due to reduced energy consumption. Fourth, the machine's brand, quality, and after-sales service also play a significant role in determining its cost.

C. Factors Influencing the Cost of Injection Molding Processes

The cost of the injection molding process is influenced by various factors. These include the cost of raw materials, which can vary depending on the type of plastic used, market conditions, and supplier relationships. Labor costs also play a vital role, especially in regions where labor costs are high. Additionally, the complexity of the mold design, the production volume, and the required precision level can significantly impact the injection molding cost. Lastly, overhead costs such as utilities, maintenance, and factory space also contribute to the overall injection molding process cost.

4.Injection Molding Machine Pricing

Varieties of Injection Molding Machines and their Pricing

In the world of injection molding, there is a wide range of machines to choose from, each with its own unique set of features and pricing. The injection molding machine cost varies significantly based on the type of machine, its size and capacity, its features, and the technology it employs.

Hydraulic Injection Molding Machines

Hydraulic injection molding machines are the traditional workhorses of the industry. They use hydraulic systems to generate the force needed to inject the molten plastic into the mold. These machines are generally cheaper than their electric and hybrid counterparts, making them a popular choice for smaller businesses or those with lower production volumes. However, they may be less energy-efficient and slower than other types of machines.

Electric Injection Molding Machines

Electric injection molding machines, on the other hand, utilize electric motors for all their movements, offering superior precision, speed, and energy efficiency. They are quieter and cleaner than hydraulic machines but come at a higher initial injection molding machine cost. Despite the higher upfront cost, the overall operating cost can be lower due to reduced energy consumption and maintenance requirements.

Hybrid Injection Molding Machines

Hybrid injection molding machines aim to combine the best of both worlds. They use hydraulic power for large, brute force movements and electric power for smaller, precise movements. These machines provide a balance between the cost-effectiveness of hydraulic machines and the precision and energy efficiency of electric machines. However, the initial injection molding machine cost can be higher than that of purely hydraulic machines.

The Role of Machine Size and Capacity in Pricing

The size and capacity of an injection molding machine play a significant role in its pricing. Larger machines with higher clamping force, larger shot sizes, and greater capacity tend to be more expensive. These machines are typically used for producing larger or more complex parts. However, a larger machine also means higher energy consumption, which should be factored into the overall injection molding cost.

Influence of Technological Advancements and Features on Machine Price

Technological advancements and additional features can also significantly influence the injection molding machine cost. Machines equipped with advanced features such as programmable logic controllers (PLCs), touch-screen interfaces, closed-loop control systems, and automation capabilities can command a higher price. However, these features can also enhance productivity, improve product quality, and reduce waste, thus potentially offsetting the higher initial investment over the machine's lifetime.

5.Injection Molding Process Cost

Role of Mold Design in Costing

The mold design plays a crucial role in determining the injection molding cost. A complex mold with intricate parts or requiring high precision will be more expensive to design and manufacture. Furthermore, the mold's life expectancy, which is influenced by the design and the materials used, can significantly impact the overall cost of the injection molding process. A longer-lasting mold can spread its cost over more parts, thereby reducing the cost per part.

The Impact of Material Selection on Molding Cost

The selection of material is another vital factor that influences the injection molding cost. Different types of plastics have varying costs, with advanced engineering plastics generally being more expensive than commodity plastics. Furthermore, the material's properties, such as its melting temperature and viscosity, can affect the energy consumption and the wear and tear on the machine and mold, thereby impacting the overall process cost.

Labor Costs in Injection Molding

Labor costs are a significant component of the injection molding cost. This includes the wages of the operators running the machines, the technicians maintaining the machines and molds, and the engineers designing the molds and optimizing the process. In regions where labor costs are high, automation can help reduce the labor cost component of the overall process cost.

Energy Consumption and its Effect on Molding Cost

Energy consumption is a major contributor to the injection molding cost. The machines need to heat the plastic to its melting point and then cool the molded part before it can be ejected. Both heating and cooling require a significant amount of energy. Therefore, energy-efficient machines and process optimization can help reduce the energy cost component of the overall process cost.

6.Strategies to Optimize Costs

How to Choose the Right Injection Molding Machine for Your Business

Choosing the right injection molding machine for your business is critical to optimizing costs. The right machine will depend on the types of parts you plan to produce, the materials you will use, your production volumes, and your budget. An oversized machine will waste energy and resources, while an undersized machine might not meet your production requirements. Also, consider the machine's energy efficiency, maintenance requirements, and the injection molding machine cost.

Reducing Costs Through Efficient Mold Design

Efficient mold design can significantly reduce injection molding costs. This includes designing for manufacturability, which means creating a design that is easy to manufacture and doesn't require complex or costly machining processes. Use of simulation software can help optimize the mold design, reducing the risk of costly design changes down the line. Additionally, choosing the right mold material can improve the mold's lifespan, thereby spreading its cost over more parts.

Energy-Efficient Practices in Injection Molding

Adopting energy-efficient practices can also help reduce injection molding costs. This includes using energy-efficient machines, optimizing the process parameters to reduce energy consumption, and using automation to minimize waste and improve consistency. Additionally, regular maintenance can keep the machines running at their peak efficiency, thereby minimizing energy waste.

7.Future Trends in Injection Molding Costs

The Potential Impact of Automation and AI

The advent of automation and AI holds significant potential to influence future injection molding costs. Automation can reduce labor costs and improve productivity, while AI can optimize process parameters in real-time to maximize efficiency and quality. These technologies may entail upfront investment but have the potential to reduce costs and increase competitiveness in the long run.

Green Manufacturing and Sustainability: The Future of Injection Molding?

Green manufacturing and sustainability are becoming increasingly important in the manufacturing industry, including injection molding. Using recyclable materials, reducing energy consumption, and minimizing waste can not only reduce injection molding costs but also make the business more environmentally friendly. As regulatory pressure and consumer demand for sustainability grow, these practices are likely to become more prevalent in the future.

Conclusion

Decoding the intricate dynamics of injection molding machine cost and mold costing requires a reliable partner. Log Machine, as an expert in injection molding solutions and equipment manufacturing, is here to assist you. With a variety of high-quality injection molding machines and a commitment to customer service, Log Machine helps businesses like yours navigate the complexities of injection molding and achieve cost-effectiveness. Discover more about how Log Machine can help your business by visiting our website: https://www.log-machine.com/.

Read More:

How to select a Plastic Injection Molding Machine

Top 10 Injection Molding Machine Manufacturer in World(2023 Updated)

2023 Top 30 China Injection Molding Machine Manufacturer Brands: Ultimate List

Electric VS Hydraulic Injection Molding Machine

Injection Molding Machine Maintenance: What You Need to Know