With the development of the injection molding industry, the types of injection molding machines are constantly enriched and updated. With the development of the plastics industry, users have higher and higher requirements for energy conservation and environmental protection. Energy-saving control technology for injection molding machines has received widespread attention, and innovative activities surrounding energy-saving control technology have also developed rapidly. Among them, the variable pump injection molding machine has been favored by many companies and factories, occupying a considerable part of the market.

So what is a variable pump injection molding machine? What are its characteristics? How to choose an excellent variable pump injection molding machine? Here is everything you want to know.

What is a variable pump injection molding machine

The variable pump injection molding machine is an injection molding machine that saves electric energy by simultaneously changing the displacement of the hydraulic pump. At the same time, the motor load will also change with changes in displacement. The main difference between a variable pump and a standard fixed pump is the output power. The output power of the variable pump changes with the load, while the output power of the fixed pump is relatively constant. In the case of small flow operation, the output power of the variable pump is very low. , And the output power of the fixed pump is basically constant.

At present, the control technology of proportional variable pump is dominant in this field. Many Chinese injection molding machine manufacturers have developed proportional variable pump systems. As the proportional variable pump system becomes more and more widely used, some manufacturers have also adopted variable frequency speed regulation systems and all-electric servo control systems. These development directions fully reflect the theme of energy conservation and environmental protection, and represent the overall development trend.

Variable pump injection molding machine characteristics

In addition to the advantages of the traditional proportional control system, the variable pump system has other characteristics.

Advantages of variable pump injection molding machine:

-

High power saving rate

The use of advanced microcomputer control technology makes the quantitative pump an energy-saving variable pump. The proportional variable pump system has good adaptability, and its output pressure and flow can be consistent with the load demand, which solves the problem of inadaptability of the flow and pressure of the throttle speed control system. The hydraulic system of the injection molding machine works in the same way as the whole machine. Need power matching, no high-voltage throttling and overflow energy loss, improve system efficiency. The power saving rate is as high as 25%-65%.

-

High reliability

Keep the original control mode and oil circuit of the injection molding machine unchanged. Computer monitoring, prompt sound and light alarm when faults are found. The mains/energy-saving operation control method is adopted to prevent malfunctions from affecting production.

-

Soft start

Reduce the vibration of mold opening and closing, and extend the service life of equipment and molds. Reduce noise and improve working environment. The heating of the system is obviously reduced, the oil temperature is stable, and the cooling water consumption of the injection molding machine can be saved by more than 30%. Reduce system heating and extend the service life of hydraulic components. Extend the service life of sealing elements, reduce downtime and maintenance rate, and save a lot of maintenance costs.

-

Simple operation

It runs synchronously with the injection molding machine without any adjustments.

-

High rate of return

By saving electricity, the entire investment of the injection molding machine's electricity saving can be recovered in about 6 months.

Limitations of variable pump injection molding machine:

-

The energy-saving effect is almost impossible for injection molding of general products and thin-walled products, especially high-speed production. This energy-saving effect is only obvious for products that require long-term high-pressure holding.

-

Poor response speed and stability will increase maintenance costs and reduce machine life.

-

The cleanliness of the hydraulic oil system of the variable pump is higher than that of the general models. In other words, the oil circuit system of the variable machine has poor anti-fouling performance and high oil circuit maintenance costs.

Recommendations for choosing variable pump injection molding machine manufacturers

The injection molding machine industry is constantly changing and developing, and the technology is constantly improving. More and more variable pump injection molding machine products appear on the market. Choose a suitable and reliable injection molding machine to obtain greater benefits for your own production. Very important.

It should be noted that the variable pump injection molding machine is divided into two types: open loop and closed loop. The main difference between the two is that the closed-loop variable pump has better machine stability, but the cost is twice as high. At present, some injection molding machine manufacturers have adopted open-loop variable pumps in order to save costs. The price difference is doubled. Many manufacturers think that the products are of high quality and low price, but they think that they are cheap. They don't know that "you get what you pay for", variable pumps are still available. The energy-saving effect and stability of the machine vary greatly according to its pros and cons. Therefore, when choosing a variable energy-saving machine, pay special attention to whether the variable pump type is open loop or closed loop, because it has an absolute impact on the stability of the machine.

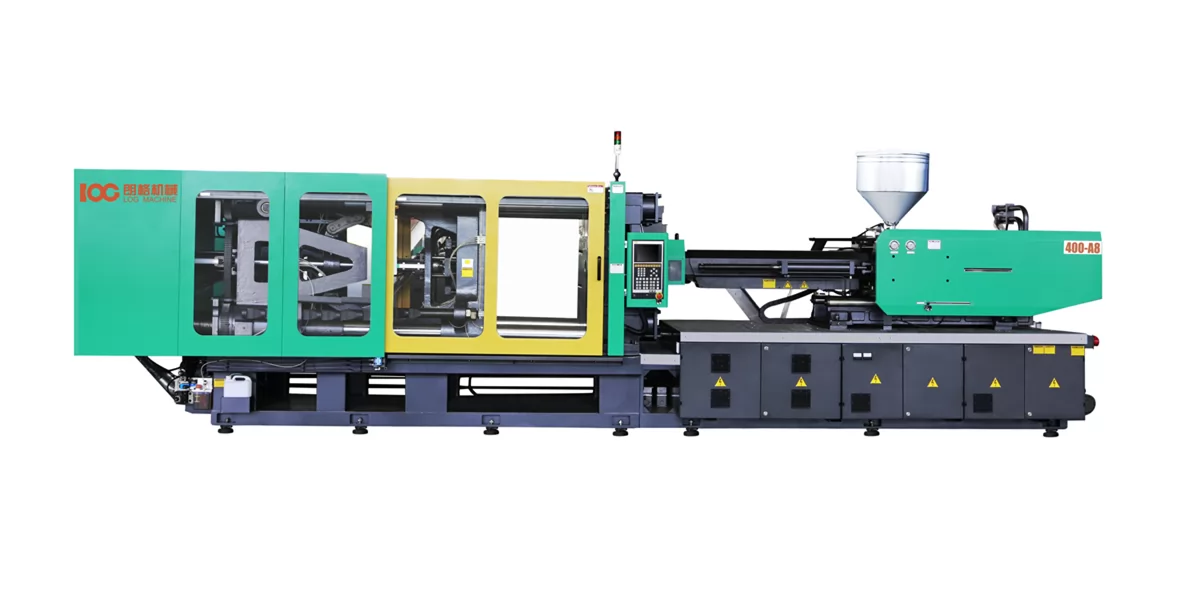

If you want to buy an excellent variable pump injection molding machine, you must carefully measure the products of each injection molding machine manufacturer. Here I recommend LOG MACHINE, the top domestic injection molding machine manufacturer. LOG MACHINE is an enterprise specializing in the production of high-tech injection molding machines, and attaches great importance to personnel training and technology development. With strong independent research and development capabilities and strict quality supervision system, it has the advantages of high efficiency, energy saving, high pressure and high speed, precision and stability. LOG MACHINE relies on years of injection molding machine manufacturing experience, keeps up with market demand, adopts foreign advanced design concepts, adopts high-precision controllers, and cooperates with energy-saving variable pumps to introduce high-precision M6 series injection molding machines to the market. market. If you are interested, you can contact us for the latest quotation and consultation.